4Industry Information

There are many types of milling cutters in precision parts processing, but only the following are commonly used.

(1) Face milling cutter: There are cutting edges on the peripheral surface and end of the face milling cutter, and the end cutting edge is the secondary cutting edge. Face milling cutters are mostly made of sleeve inserts, and the cutter teeth are made of high-speed steel or cemented carbide. Compared with high-speed steel milling cutters, cemented carbide face milling cutters have faster washing speed, higher processing efficiency, and better surface quality.

(2) End mills: End mills are the most commonly used milling cutters for precision parts processing. The cylindrical surface and end surface of the structure have cutting edges. They can be cut at the same time or separately.

The cutting edge on the cylindrical surface of the end mill is the main cutting edge, and the cutting edge on the end surface is the secondary cutting edge. The main cutter is a helical tooth, which can increase cutting stability and improve machining accuracy.

(3) Mould milling cutter: Mould milling cutter is developed by end milling cutter, which can be divided into three types: conical end mill, cylindrical ball end mill and conical ball end mill. The shank has a straight Shank, flat straight shank and Morse taper shank.

Its structural feature is that the ball head or end surface is covered with cutting edges, and the circumferential edge is connected with the ball head edge in an arc, which can be used for radial and axial feed. The working part of the milling cutter is made of high-speed steel or cemented carbide.

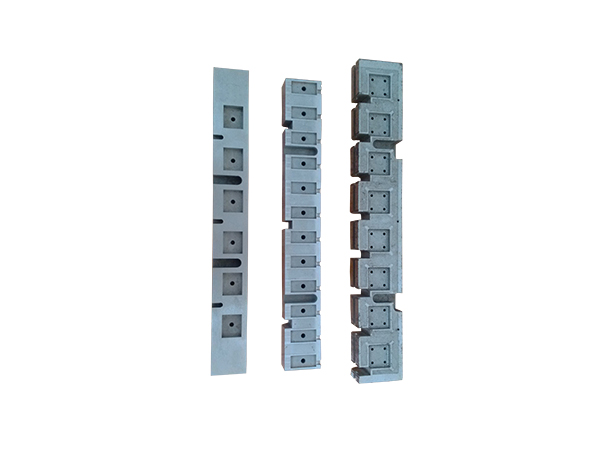

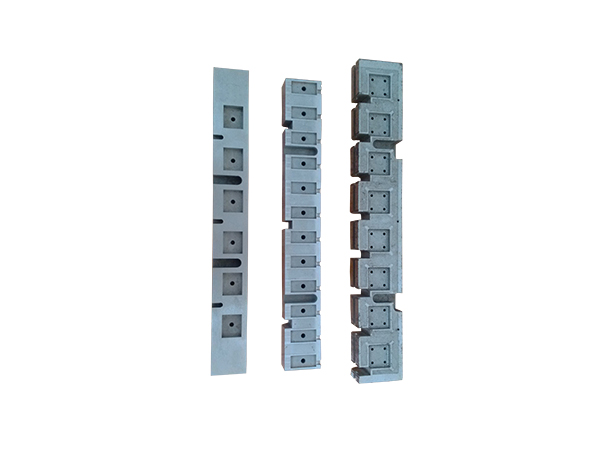

(4) Keyway milling cutter: The keyway milling cutter has two teeth, the cylindrical surface and the end surface have cutting edges, and the end surface edge extending to the center is like an end mill or a drill. When machining, the first axial feed reaches the groove depth, and then the full length of the key groove is milled out along the key groove direction.

(5) Drum milling cutter: its cutting edge is distributed on the arc surface, and the end face has no cutting edge. During processing, control the up and down position of the tool, and change the cutting position of the cutting edge accordingly, so that different bevel angles from negative to positive can be cut on the workpiece.

The drum shape can be processed in a wide range, but the surface quality obtained is worse. The disadvantages of this tool are difficult sharpening, poor cutting conditions, and not suitable for processing bottomed contour surfaces.

(6) Forming milling cutters: Forming milling cutters are generally designed and manufactured specifically for specific workpieces or processing content, such as angle faces, grooves, special-shaped holes or tables, etc.

In addition to the above milling cutters, various general milling cutters can be used for precision parts processing. However, because many machine tools have special broach positions in the spindle, or because the taper holes in the spindle are different, transition sleeves and pull studs must be prepared.