4Industry Information

Principles represent the attitude of being a person and doing things, and precision parts processing is no exception. Each step also has its principles.

(1) The principle of datum surface first: The surface used as a precision should be processed first, because the more accurate the surface of the positioning datum, the smaller the clamping error.

(2) The principle of first roughing and finishing: follow the order of roughing, semi-finishing, finishing, and precision processing to process each surface in order to gradually improve the surface processing accuracy and reduce the surface roughness value.

(3) The principle of primary and secondary: The main working surface of the part and the bottom surface of the component should be processed first in order to find possible defects on the main surface of the blank as soon as possible. The secondary surface can be interspersed, placed on the main processing surface to a certain degree, before finishing.

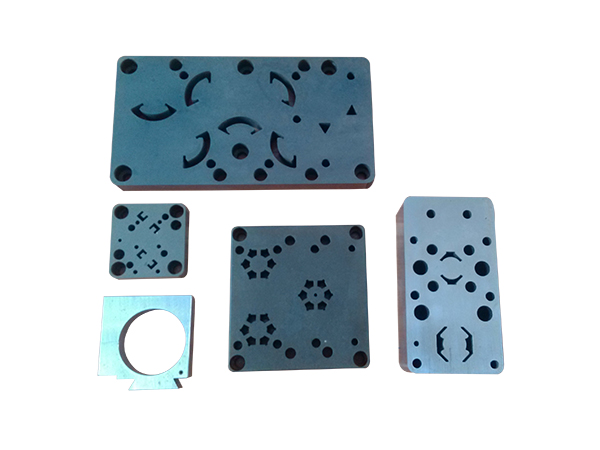

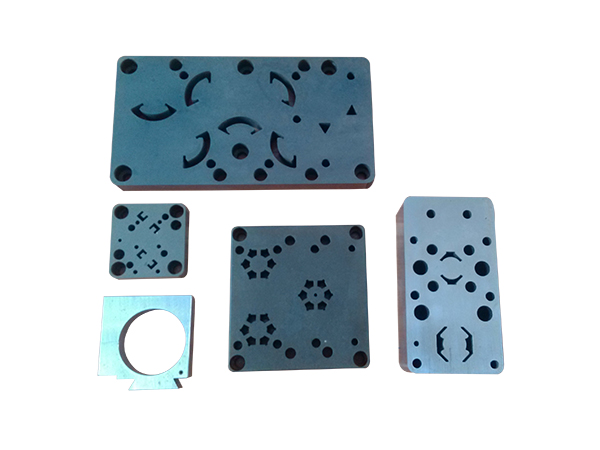

(4) The principle of surface first and hole second: For box and bracket parts, the dimensions of the plane contour are compared. For precision parts processing, the plane is generally processed first, and then the holes and other dimensions are processed. In this way, the processing sequence is arranged, on the one hand, the processed plane is used. The positioning is stable and reliable. On the other hand, it is easier to machine holes on the machined plane, and can improve the machining accuracy of the holes, especially for drilling, the axis of the hole is not easy to deviate.

The above four processing principles can be related to the quality of product processing, so it is necessary to understand these four processing principles first when precision machining.